Specification:

|

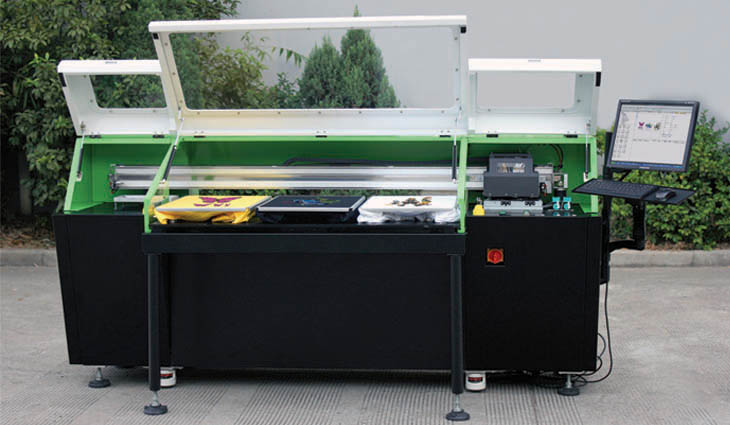

Focus Aladdin-Jet

|

|

Printhead

|

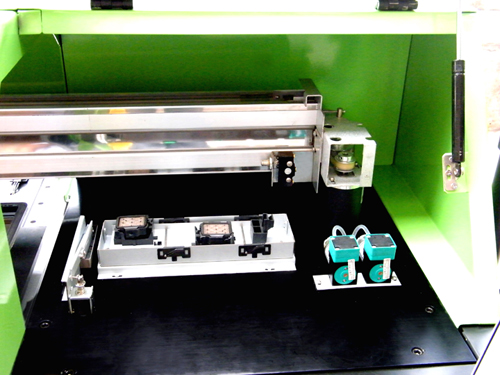

2/4 epson DX5 2/4epson DX7 piezo print head

|

|

Print Color

|

2*CMYK+2*CMYK

|

|

2*CMYK+WWWWWWWW (White)

|

|

Color channel setting

|

Optional choose

|

|

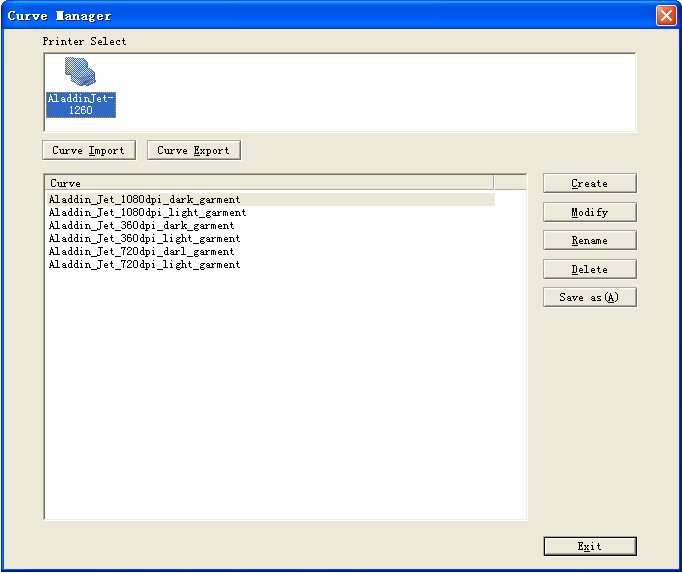

Color management

|

ICC curve

|

|

Max. Printing size

|

1250mm*600mm

|

|

Pallet size

|

40*50cm standard shirt pallet*3pcs

|

20*20cm baby shirt pallet*2pcs

|

|

40*60cm large shirts pallet*3pcs

|

20cm*60cm sleeve pallet*2pcs

|

|

Printing Direction

|

Uidirection / Bidirection

|

|

Printing speed (40*50cm area)

|

2*CMYK+ 2*CMYK Bidirection

|

2*CMYK+8*White Bidirection

|

|

0:51 720*360dpi

|

1:03 720*360dpi

|

|

1:03 720*720dpi

|

1:27 720*720dpi

|

|

1:45 720*1080dpi

|

2:15 720*1080dpi

|

|

2:19 720*1440dpi

|

3:21 720*1440dpi

|

|

3:47 720*2160dpi

|

4:55 720*2160dpi

|

|

4:38 720*2880dpi

|

5:57 720*2880dpi

|

|

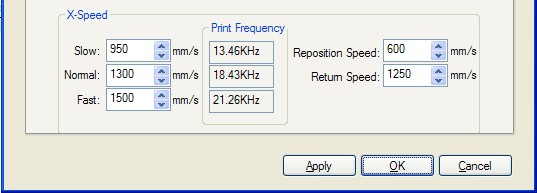

Carriage motion frequency

|

600-2000mm/s optional

|

|

Ink dot jet frequency

|

1Hz-2000Hz optional

|

|

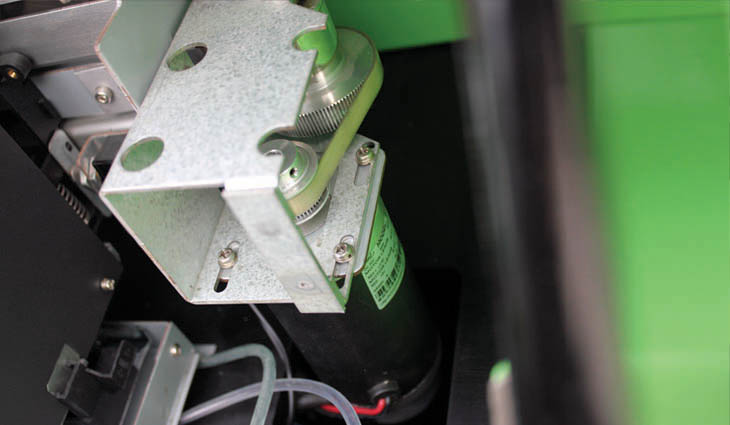

Carriage drive type

|

DC servo motor

|

|

Table drive type

|

AC servo motor

|

|

Guide type

|

Linear rail

|

|

Ink dot type

|

1bits, 2bits, dark, halfton, real time

|

|

Fire type type

|

Rand, fog, wave, 2D

|

|

Head maintainance type

|

Wet-cap system / Idle flash system

|

|

Control type

|

computer Intelligent

|

|

Printing resolution

|

720*360dpi / 720*540dpi/ 720*720dpi/ 720*1080dpi 720*1440dpi / 720*2160dpi/ 720*2880dopi

|

|

Color Ink Tank Volume

|

250ml non-chips bulk supply

|

|

White ink tank volume

|

500ml non-chips bulk supply

|

|

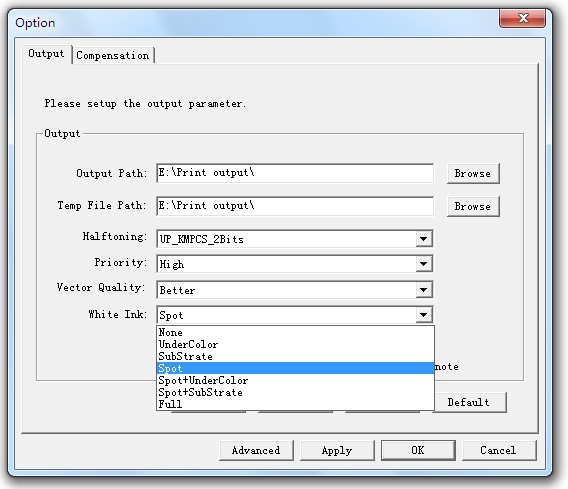

White ink print type

|

Spot, gardient, UnderColor, Substrate, Spot+substrate, Spot+Under color

|

|

Ink type

|

DTG ink/ sublimation ink/ reactive ink/ discharge ink/ eco solvent ink/ CTS ink.

|

|

Ink process

|

Filter system+white ink shaking system+white ink circulation system

|

|

Printhead Protection

|

Intelligent Self Protect System

|

|

Power

|

110-220V 50-60HZ 250W

|

|

Printing Interface

|

USB2.0/LTP

|

|

Operation System

|

Win2000/ WinXP/.Win7

|

|

Working Environment

|

50%humidity, 21-29¡æ

|

|

Printer Size

|

L2350mm*W650mm*H620mm

|

|

Shipping Size

|

L2600mm*W720mm*H760mm

|

|

Printer N.Weight/G.Weight

|

320KG/365KG

|

View:

.jpg) .jpg) .jpg) .jpg)  .jpg)

.jpg)

.jpg)

Technical features:

1. Unique design

Focus Aladdin-Jet direct to garment printer is not as others paper modified DTG printers, it is a real industrial dtg direct to garment printer that all build by focus digital except the print head.

2. Two / Four head creation.

Aladdin-Jet was mounted with 2 eposn DX5/DX7 print head for standard model, while it can be also updated to 4 heads, 8 heads model without change system.

3. One move pass printing type.

Print the white and color ink by one carriage move pass, save half time than the traditional printing twice method.

4. Own build electronic system.

Printer is working under Focus created electronic system, no epson, no mutoh or Mimaki, intelligence error alarm, auto motion step adjustment, Automatic Print head anticreep; Aumatic electronic board anticreep; EMI protected...

5. High precision driver system.

AC/DC servo motor to drive the X.Y axis moving with high precision.

6. Strong mechanial motion build.

#20-05 ABBA good rigid ball screw go with HIWIN linear rail to guide the table motion.

7. One-stop pallet family.

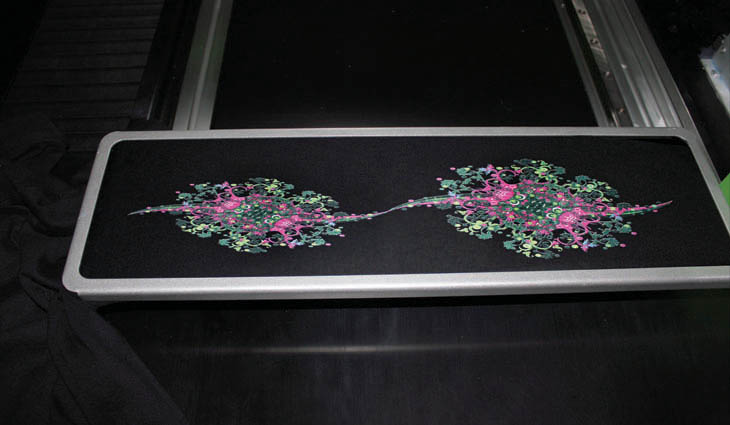

The motion flatbed table was mounted with 21pcs high precision flangle. you can exchange the pallet for print on different media with different size, shape on several seconds. it can support to print on 3pcs* 40*60cm large size / 3pcs* 40*50cm standard size / 2pcs*20*20cm baby shirts / 2pcs*20*60 sleeves & pants in one time.

8. Auto idle / during printing FLASH jet design.

The auto idle / during printing flash jet design can prevent the nozzle clog while the printer is idle. you can set the flash jet frequency from 1HZ to 1000HZ. so even some noozles got clogged, you can flash out by a certain large frequency.

.jpg)

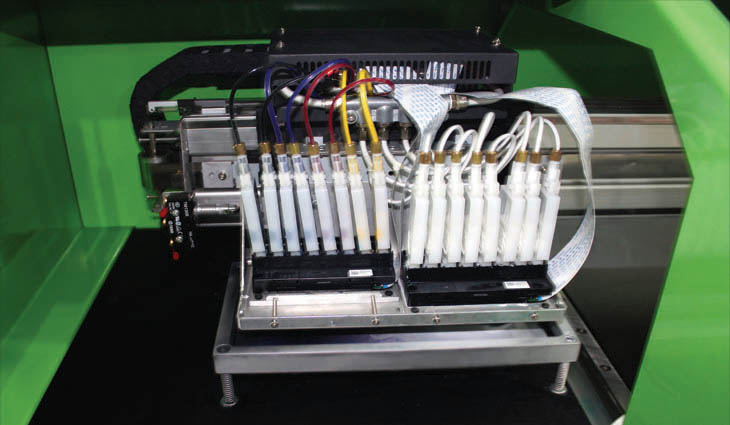

9. Bulk ink supply system for color and white ink.

Both white and color ink are use the bulk supply system with ink filter, air filter for each color, also the non-chips design can let you far away from reset the ink chips, no ink cartridges headache.

10. With white ink process system.

The Aladdin-Jet industrial direct to garment printer is mounted with Auto white ink feed system, White ink shaking system and White ink circulation system, it can solve out the problem of white ink settling to prevent the print head.

.jpg)

11. Individual multi-functional cap station design

The individual cap station design can save lots of ink during head cleaning as you can choose 1st head or 2nd head to clean, the clean pumping time, pumping pressure can be setted. You can also set the wip time, waiting time to release the print head and ink damper air pressure after purage, the individual design can also prevent the white ink and color ink mixing during head cleaning and maintain after printing. You can aslo choose KEEP WET to drive the print head back to cap station for prevent nozzle clog if pause print for several hours. The auto cap cleaning system can help you to wash the cap station, wiper and maintain print head after printing easier.

12. High speed.

Two heads print with 2*CMYK+8*White can finish a 30cm*30cm by 1:05mins, while only cost 47s when print with 2*CMYK+2*CMYK. You can set the head fire frequency, carriage motion frequency custom.

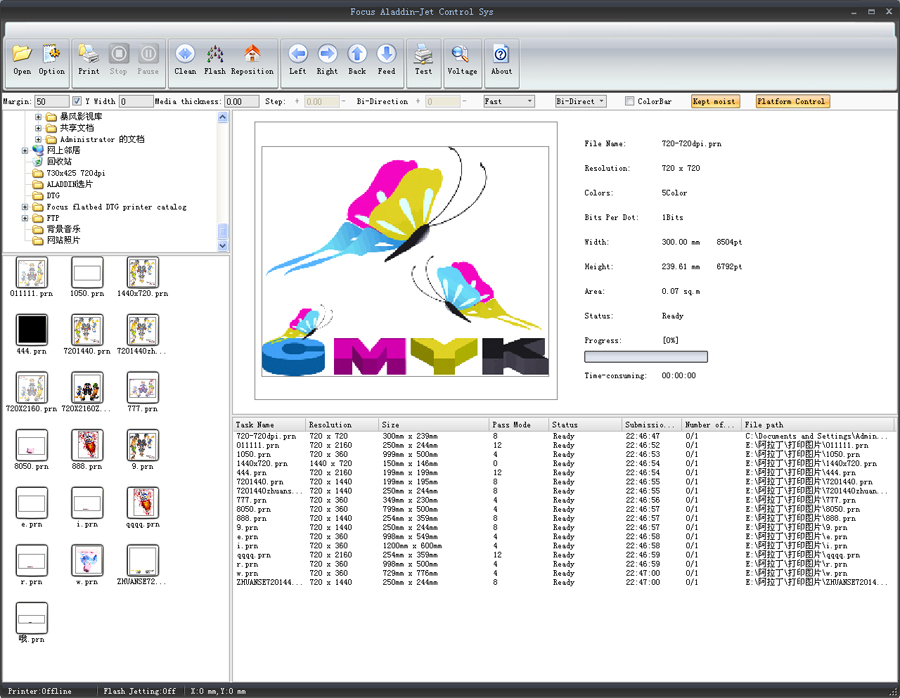

13. Powerful and humanizing control system.

The Aladdin-Jet control system can finish all working orders by your mouse. It can control the flatbed forward, backwoard, carriage to left, to right, flash jet on/off; Keep wet. printing pause/stop; Support ink dot jet type by : RAND / WAVE / FOG / 2D; Automatic step and X. Y gear ratio adjustment; skip-empty pixel printing; white ink printing by SPOT / TOP / BOTTOM / Motion frequency set optional....

Please click here for more information about Aladdin-Jet control system.

14. Good performance color management

Good color management with built-in color.icm and custom ICC curve adjustment.

15. Free update of Firmware and Logic for all customers all the time.

Video demo

|