2. High temperature oxidation treatment of paint, prevent color off and anti-scratch.

3. Strong mechanical making, 5mm thickness metal frame, 20mm thickness aluminium plate flatbed, all mechanical spareparts made from high quality aluminium, insure all parts working stable without distortion and flatbed moving without shake and excursion after longtime working.

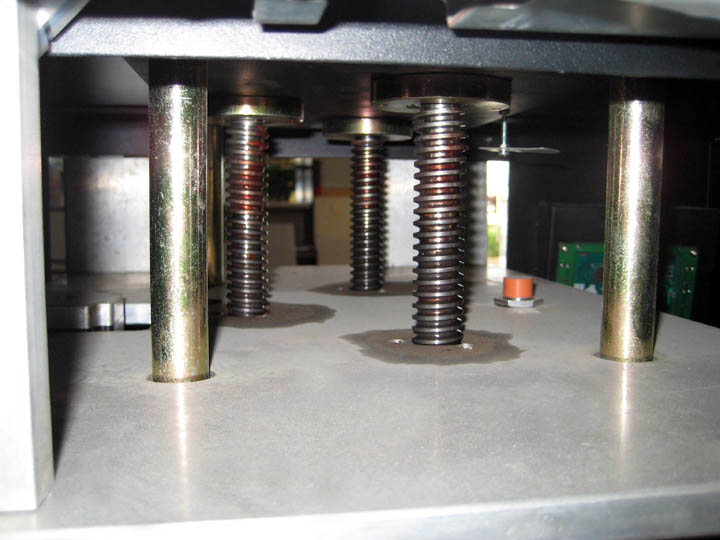

4. Grinding treatmented ball screw guide rail go with dual cylindrical rail for Y axis motion. Driver the flatbed motion with high precision.

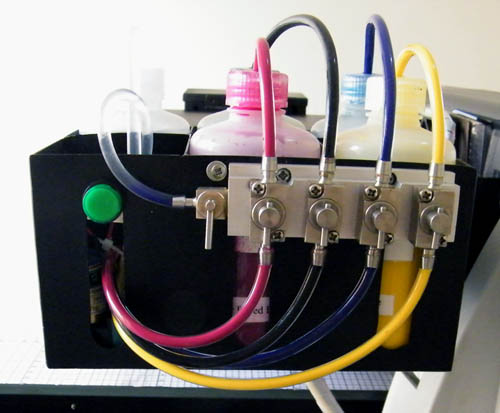

5. Focus Butterfly-Jet no need to use the cartridges, instead of bulk ink bottle supply system, it is easy to refill ink, also unique designed automatic one step cleaning solution chanel make more convinence for customers exchange ink, wash ink tube, cleaning print head. Just press one button, all colors can be washed quickly.

6. Focus newest WIPS white ink processing system also created for customers print with white ink to dark media, it is a good solution for titanium white ink settling and head clog, there are include White Ink Shaking System, White Ink Circulation System, One Step Flushing System. The shaking speed, shaking time, circulation flow rate, circulation time are also adjustable.

.gif)

7. USA paul brand ink filter can filt the impurity of the ink to prevent the head clog.

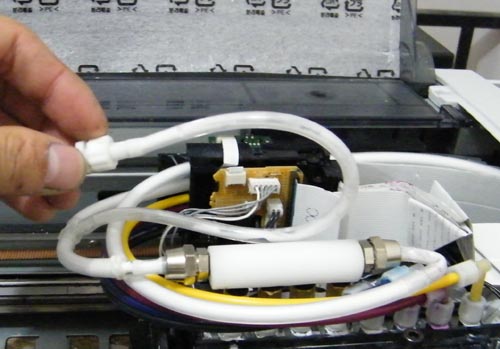

8, Extra tube with three-way-valve easy for customer flush print head without take out print head, just put the tube inside head cleaning solution and press the solution charge button, then all nozzles got flushed, no need to remove the heads for filling manual, it is most used for daily maintainance.

9. Modified waste ink container also make customer convinence for load ink and maintain head.

10. Pr-heating system with dual far infrared rays can got max. 400 degree under 30 seconds. it is very useful when print the cotton garments and the hard rigid media, as the ink can be adsorbed well by the media to get a good washness and anti scratch.

11. Vacum fan were mounted at he back of print head to pull hot air out for prevent the ink dry inside print head.

12. Automatic up and down limit detecting by industrial red ray sensor. Can prevent the print head and flatbed scratching during printing.

13. Four pieces T type screw guide go with copper nut. make the Z axis motion stable to achieve the printing flatbed surface level on any position.

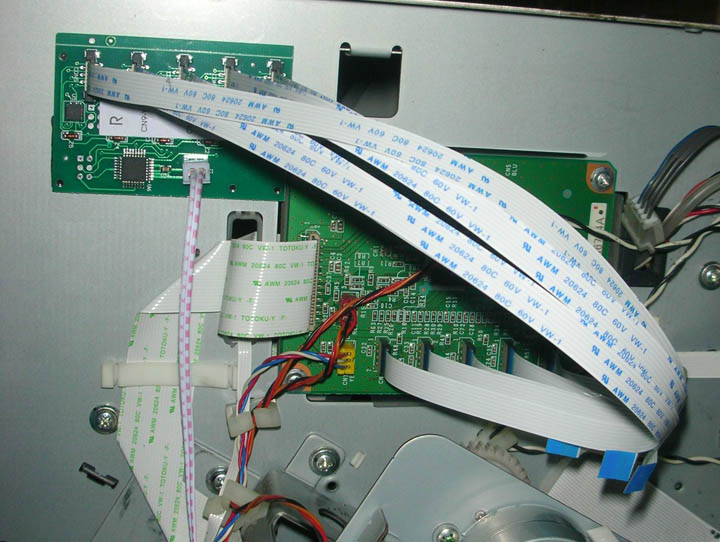

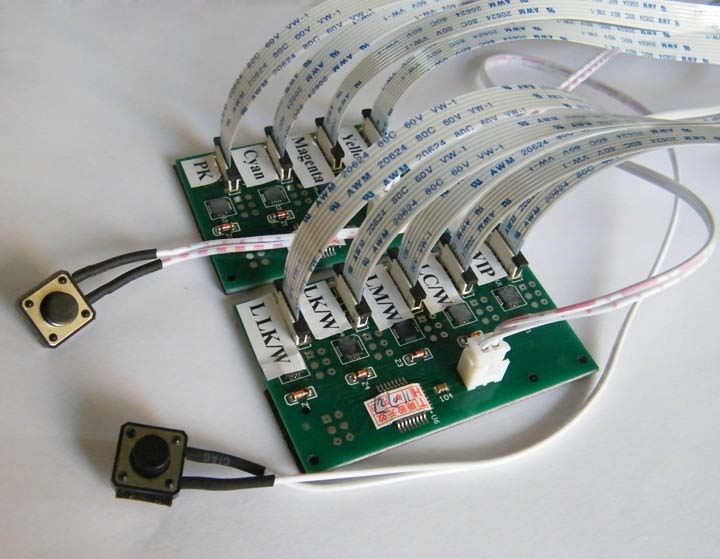

14. Single chip board control system can control the flatbed move forward, backward, up, down, auto online, auto offline, continus cycle printing easy.

15. Focus newest created ink carriage chips reset system and waste ink pad reset system. Can remove your headache for printer can not recognize chips. Just press a reset button all chips will be reseted.

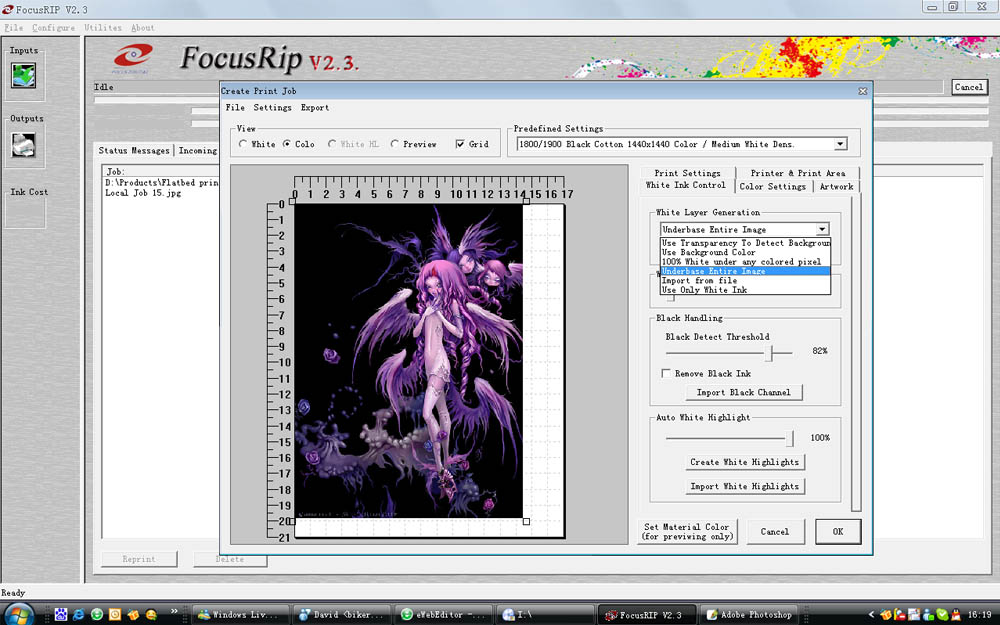

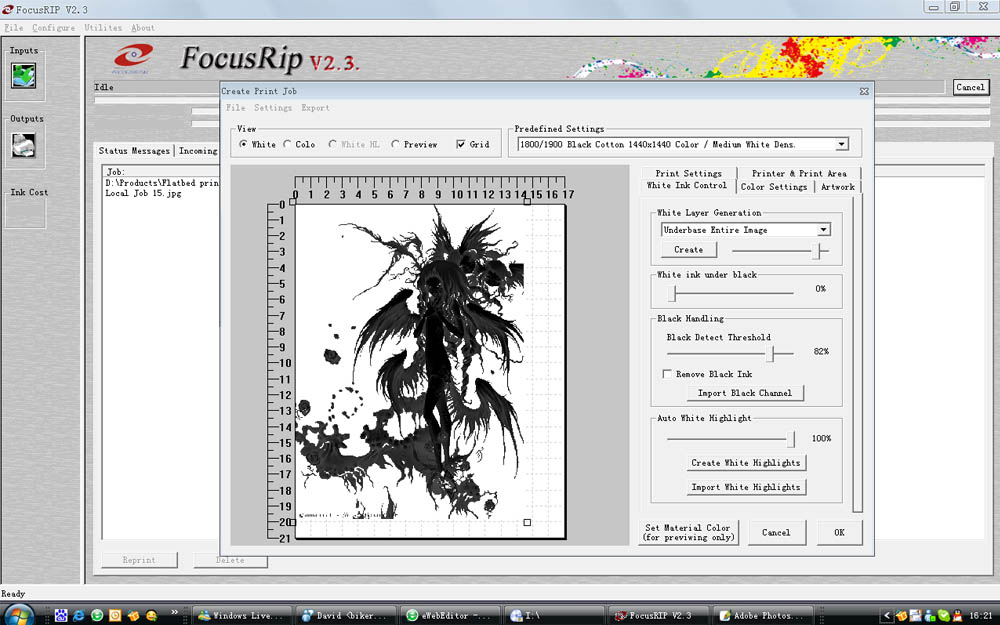

16. Matching Professional FocusRip white rip and printing software, Get better graphic raster and rapid result while printing with white ink. Powerful function such as clor management, color channel divide management, ICC optional, Whiteness adjustable.

Click here to learn more about FocusRIP

17. Optional solution

A: Solution for sign area when print with eco solvent ink.

B: Solution for dtg area when print with textile ink.

C: Solution for Edible area when print with edible ink. such as cake.

D: Solution for CTS computer direct to screen area for make the digital screen plate when print with CTS ink.

3 Application field:

<1>. Sign making shop

<2>. Photo studio or film development shop

<3>. Screen printing, direct to screen imaging system

<4>. Garment,Textile and fabric, such as the T-shirt, flag, handkerchief, neckerchief...

<5>. Leather, shoes, clothes, crystal and other crafts & gifts industries

<6>. All kind of factories of art items with image

etc...

It is a compliment to screen printing production and heat-transfer industries as it can do some jobs which are very expensive or not possible with the traditional printing.