| The workflow of Focus CTS-160ES flat bed engraver machine.

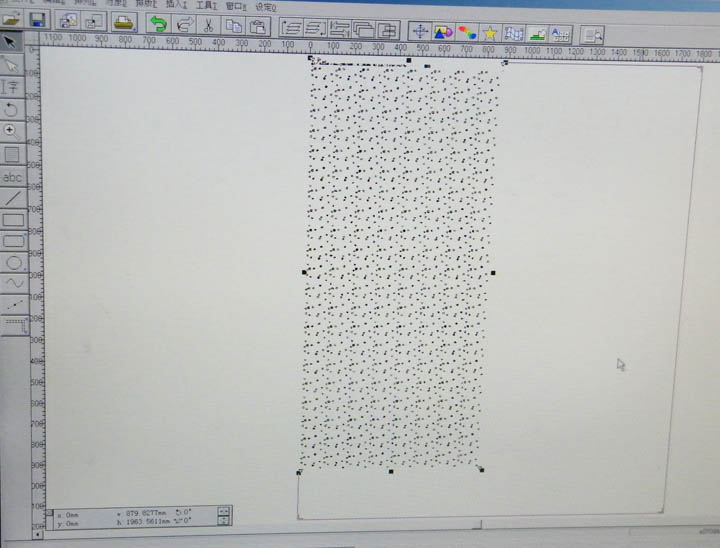

1. Color separation. separate each color from Photoshop. coreldraw or other professional color separation software.

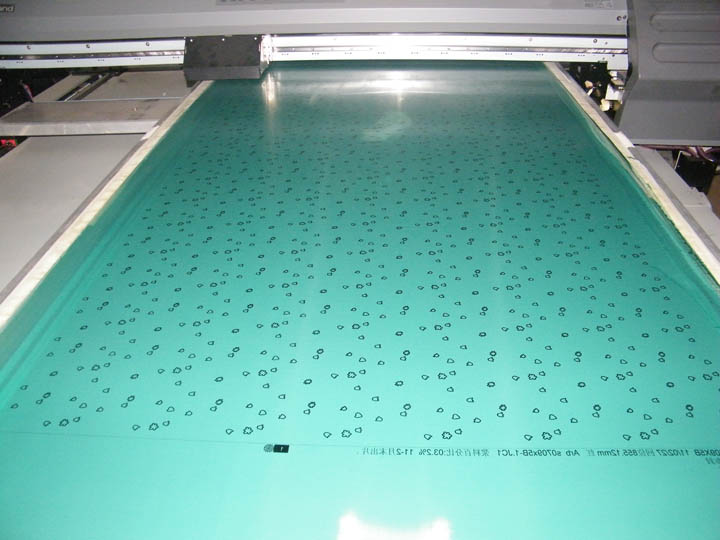

2. Screen loading. Coated screen preparing. Make the screen size with needed. coat with emulsion, then Load the screen to the printer flatbed. tighten

the screw at each angle of flatbed horizontal.

3. Printing. Start printing from computer directly.

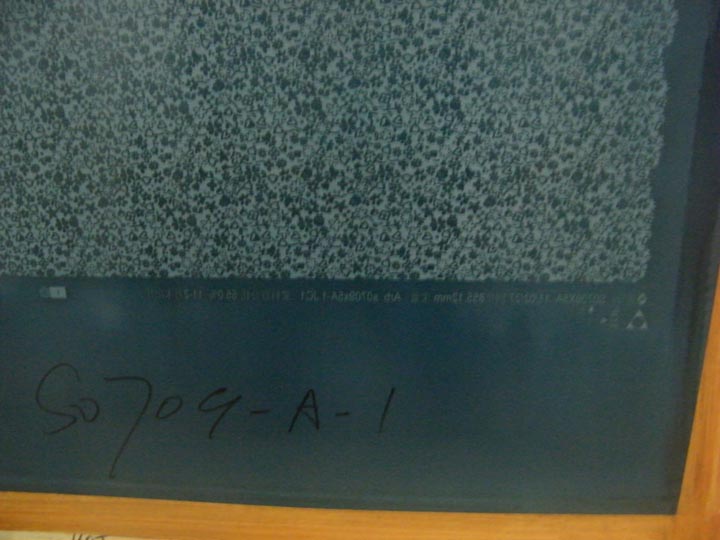

4. Developing. develop the printed screen under the light.

5. Washing, the print jetted ink will be washed off because it is wate based ink.

6. Heating.

Finish. After the above 6 steps, the finished screen can be used for screen printing now.

------Authored by Focus digital techmology co.,ltd. support team. www.focusdgt.com |