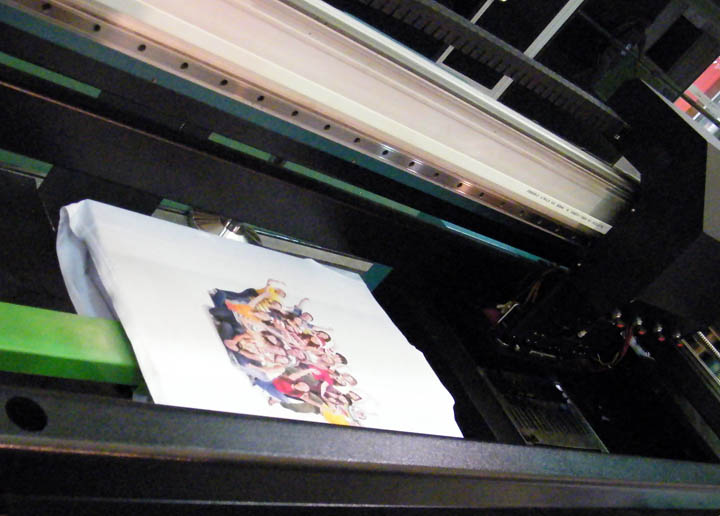

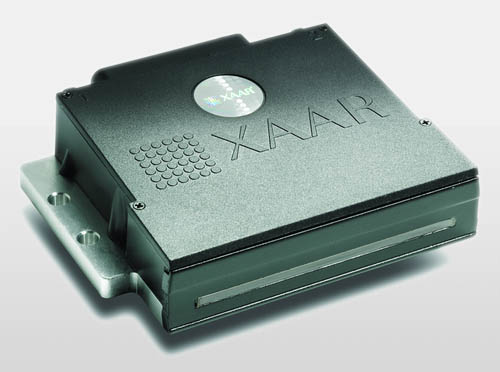

Focus Athena 960 series industrial direct to garment printer, DTG digital printer was made for high quality, high speed DTG printing, it is not a normal epson paper converted flatbed printer, but use 6-16 pieces XAAR industrial DOD( Drop on demand) piezo electric print head which is made in UK. with auto pre treatment spray system, auto post heating system, negotive ink supply system, SPWS Single Pass White ink printing System etg. which is created by focus digital. which can also be connected with screen printer. Can really achieve your high speed, high quality DTG printing demands.

*Technical features:

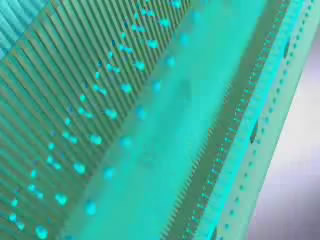

1. High printing performance of print head. 6-16 pieces Industrial XAAR brand DOD(Drop on demand) Piezo electronic can get max printing speed by 51.2m²/Hour, Equal to 300 pieces Tshirt /hour under 30cm*40cm printing size. 128 nozzles per each heads. 16 heads total 2048 nozzles. 185 npi (nozzle per inch) nozzle density. 8.3khz fire frequency can adapter DTG water based pigment inks, dye sublimation inks, eco solvent inks freely. 40pl big ink drop volume can make inks go through nozzles without any head clog. (Epson heads is 4.5pl), this is very important when you print with white ink.

Click here to learn more about XAAR PRINT HEAD

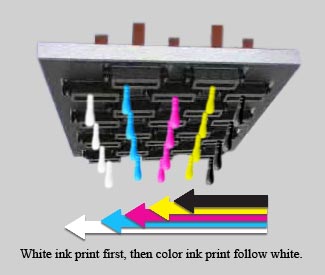

2. Fast and best way to print white ink. Focus original Proprietary SPWS system can make print white ink to dark material as easy as print on light material. SPWS is the short for "Single Pass White ink printing System". For all DTG printers since now, need to print a white layer first, then back to print on the color inks to the white layer again. it is a big headache as it is low speed, complex workflow, now by Focus SPWS system, everything make easy. Focus printer control center can control each heads jet ink independently. The white ink heads print first, then the color ink print follow the white ink finished about 0.13 seconds late. the white ink and color inks were printed by the same pass same time! no need to wait anymore. This printing technology is proprietary by focus digital.

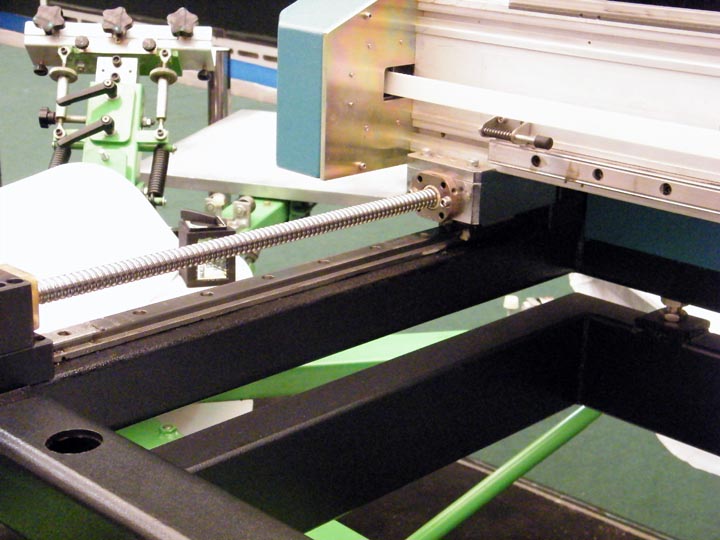

3. Combine with screen printer freely. Focus Athena 960 series have three printing pallets. can printing independently or together with screen printer. the digital and screen mixed printing quality bring your jobs to a new level.

4. Negotive pressure CISS ink system. Negotive ink supply system can make the inks apply stabilization to prevent misting.

5. Auto pre treatment spray system. No need do the pretreatment manual anymore, just press " Spray PT" button on the machine then the garments can be sprayed automatically, The flow and pressure also adjustable.

6. Particular cleaning system. Two-way valves design, one for inks and the another one for head cleaning, make the head cleaning easier.

7. Good carriage motion making. Japanese THK rail, French Megadyne belt and encode film positioning make the carriage moving smoothly.

8. High precission Y axis motion. Dual ball screw, Dual linear THK rail build for the Y axis motion with high moving precision.

*Specification:

|

Model

|

Focus Athena-960 series

|

|

Print head

|

Printing technology

|

Industrial DOD piezo electronic print head with 128 nozzles per head

|

|

Quantity

|

6/8/12/16pcs print head free optional

|

|

colors

|

5 colors (CMYK+W) / 7 colors(CMYK,LC,LM+W)

|

|

Height

|

Adjustable up to 15mm above media

|

|

Cleaning Method

|

Auto positive pressure clean and negative pressure clean system

|

|

Pre treatment Spray Control

|

Automatic spay nozzle

|

|

Printing speed

|

6 heads; (CMYK+2W)

|

13.8m²/hour; 105 Tshirts/hour (30*40cm Tshirt size)

|

|

8 heads; (CMYK+4W)

|

20.0m²/hour; 155 T-shirts/Hour

|

|

12 heads; (2xCMYK+4W)

|

31.5m²/hour; 250 T-shirts/Hour

|

|

16 heads; (3xCMYK+4W)

|

48.1m²/hour; 380 T-shirts/Hour

|

|

Ink

|

Types

|

DIrect to garment pigment water based ink

|

|

color model

|

C,M,Y,K,+W / C,M,Y,K,LC,LM+W

|

|

Supply Mode

|

Auto ink supply system

|

|

Fabric

|

Types

|

Suitable for cotton, flax, silk, wool, nylon, polyester fabric etc. ( Woven, knitted and non-woven)

|

|

Max.Thickness

|

200mm

|

|

Printing size

|

900mm*600mm

|

|

Printing. Resolution

|

360*360dpi, 360*720dpi, 720*720dpi

|

|

Print model

|

2pass. 3pass, 4pass, 6pass, 8pass

|

|

Fabric Drying System

|

Infrared dries and cool fans

|

|

Operating Interface

|

Touching screen LCD display

|

|

Printing Interface

|

USB2.0(Windows 2000/nt/xp etc.)

|

|

Work Station

|

Internal computer, P4/3.2G,,, , 1G RAM, 160G HD

|

|

Rip software

|

FocusRIP V2.5.2

|

|

File Format

|

JPEG, TIFF, BMP\RGB

|

|

Power supply

|

Voltage

|

220V/110V

|

|

Frequency

|

50HZ+_10%

|

|

Consumption

|

3KW

|

|

Compressed Air Connection

|

Air Flux¡Ý1.5m3min

|

|

Working Condition

|

Temperature 20-30 degree, Humidity 60-70%

|

|

Certification

|

CE, ISO, SASO

|

|

Printer size / Weight

|

L2200mm * W1800mm* H1550mm / 350Kg

|

|

Package size / Weight

|

L2350mm * W2000mm* H1600mm / 351Kg

|

* Demo video:

*Printed samples: